Autoclave

Autoclave

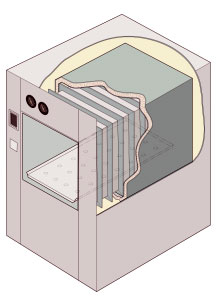

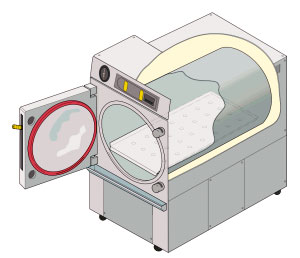

An autoclave is a device used to carry out industrial and scientific processes requiring elevated temperature and pressure different from ambient air pressure. Autoclaves are used in applications such as sterilization of medical equipment, chemical reactions, and the curing of composites.

History[edit | edit source]

The concept of the autoclave was first developed by Charles Chamberland in 1879. The invention was a significant advancement in the field of microbiology and medicine, allowing for the effective sterilization of surgical instruments and other medical tools.

Principle of Operation[edit | edit source]

Autoclaves operate on the principle of steam under pressure. The basic process involves:

- Loading the items to be sterilized into the autoclave chamber.

- Sealing the chamber and removing air from it.

- Introducing steam into the chamber at high pressure.

- Maintaining the temperature and pressure for a specified period.

- Allowing the chamber to cool and depressurize before opening.

Types of Autoclaves[edit | edit source]

There are several types of autoclaves, including:

- Gravity displacement autoclaves: These use steam to displace air in the chamber.

- Pre-vacuum autoclaves: These remove air from the chamber using a vacuum pump before introducing steam.

- Steam-flush pressure-pulse autoclaves: These use repeated pulses of steam to remove air from the chamber.

Applications[edit | edit source]

Autoclaves are used in various fields, including:

- Medicine: Sterilizing surgical instruments, laboratory equipment, and medical waste.

- Microbiology: Sterilizing culture media and laboratory glassware.

- Dentistry: Sterilizing dental instruments.

- Veterinary medicine: Sterilizing veterinary instruments and equipment.

- Industrial applications: Curing composites, vulcanizing rubber, and processing certain chemicals.

Safety and Maintenance[edit | edit source]

Proper maintenance and safety protocols are essential for the safe operation of autoclaves. Regular inspections, calibration, and adherence to manufacturer guidelines help ensure the autoclave operates effectively and safely.

See Also[edit | edit source]

References[edit | edit source]

External Links[edit | edit source]

Transform your life with W8MD's budget GLP1 injections from $125

W8MD offers a medical weight loss program NYC and a clinic to lose weight in Philadelphia. Our W8MD's physician supervised medical weight loss centers in NYC provides expert medical guidance, and offers telemedicine options for convenience.

Why choose W8MD?

- Comprehensive care with FDA-approved weight loss medications including:

- loss injections in NYC both generic and brand names:

- weight loss medications including Phentermine, Qsymia, Diethylpropion etc.

- Accept most insurances for visits or discounted self pay cost.

- Generic weight loss injections starting from just $125.00 for the starting dose

- In person weight loss NYC and telemedicine medical weight loss options in New York city available

- Budget GLP1 weight loss injections in NYC starting from $125.00 biweekly with insurance!

Book Your Appointment

Start your NYC weight loss journey today at our NYC medical weight loss, and Philadelphia medical weight loss Call (718)946-5500 for NY and 215 676 2334 for PA

Search WikiMD

Ad.Tired of being Overweight? Try W8MD's NYC physician weight loss.

Semaglutide (Ozempic / Wegovy and Tirzepatide (Mounjaro / Zepbound) available. Call 718 946 5500.

Advertise on WikiMD

|

WikiMD's Wellness Encyclopedia |

| Let Food Be Thy Medicine Medicine Thy Food - Hippocrates |

Translate this page: - East Asian

中文,

日本,

한국어,

South Asian

हिन्दी,

தமிழ்,

తెలుగు,

Urdu,

ಕನ್ನಡ,

Southeast Asian

Indonesian,

Vietnamese,

Thai,

မြန်မာဘာသာ,

বাংলা

European

español,

Deutsch,

français,

Greek,

português do Brasil,

polski,

română,

русский,

Nederlands,

norsk,

svenska,

suomi,

Italian

Middle Eastern & African

عربى,

Turkish,

Persian,

Hebrew,

Afrikaans,

isiZulu,

Kiswahili,

Other

Bulgarian,

Hungarian,

Czech,

Swedish,

മലയാളം,

मराठी,

ਪੰਜਾਬੀ,

ગુજરાતી,

Portuguese,

Ukrainian

Medical Disclaimer: WikiMD is not a substitute for professional medical advice. The information on WikiMD is provided as an information resource only, may be incorrect, outdated or misleading, and is not to be used or relied on for any diagnostic or treatment purposes. Please consult your health care provider before making any healthcare decisions or for guidance about a specific medical condition. WikiMD expressly disclaims responsibility, and shall have no liability, for any damages, loss, injury, or liability whatsoever suffered as a result of your reliance on the information contained in this site. By visiting this site you agree to the foregoing terms and conditions, which may from time to time be changed or supplemented by WikiMD. If you do not agree to the foregoing terms and conditions, you should not enter or use this site. See full disclaimer.

Credits:Most images are courtesy of Wikimedia commons, and templates, categories Wikipedia, licensed under CC BY SA or similar.

Contributors: Prab R. Tumpati, MD