Connecting rod

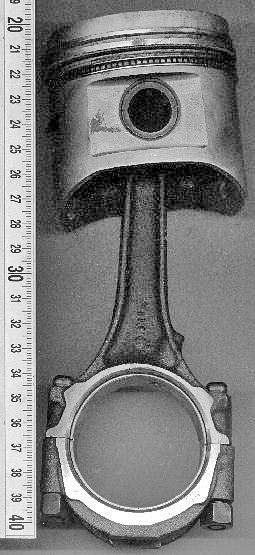

Connecting rod is a crucial component in various types of internal combustion engines and compressors. It plays a significant role in converting the reciprocating motion of the piston into rotational motion at the crankshaft. This process is fundamental to the operation of engines and compressors, making the connecting rod an essential part of their mechanical structure.

Design and Function[edit | edit source]

The design of a connecting rod is tailored to endure high levels of mechanical stress during operation. Typically, it is made from durable materials such as steel or aluminum, depending on the specific requirements of the engine or compressor, including factors like weight, strength, and cost. The connecting rod consists of two main parts: the big end and the small end. The big end connects to the crankshaft and has a bearing to facilitate smooth rotation, while the small end connects to the piston's gudgeon pin, allowing the piston to move.

In operation, as the piston moves up and down within the cylinder, the connecting rod translates this motion into the rotational movement of the crankshaft. This conversion is critical for the functioning of the engine, as it drives the vehicle's wheels or the compressor's mechanism.

Materials and Manufacturing[edit | edit source]

Modern connecting rods are manufactured using various processes, including forging, casting, and machining, to achieve the desired strength and durability. High-performance engines, such as those used in racing cars or aerospace applications, often use advanced materials like titanium or specialized alloys. These materials provide the strength needed to withstand the extreme conditions of high-speed operation while minimizing weight to enhance overall performance.

Types of Connecting Rods[edit | edit source]

There are several types of connecting rods, each designed for specific applications and engine types. Some common variations include:

- Plain Connecting Rods: The most basic and commonly used type, suitable for most standard engines. - I-Beam and H-Beam Connecting Rods: These rods are named after their cross-sectional shapes and are used in high-performance and racing engines for their superior strength and weight characteristics. - Fracture Split Connecting Rods: A modern manufacturing technique where the rod is intentionally broken to create a more precise mating surface at the big end. This process improves the fit and strength of the connection.

Challenges and Innovations[edit | edit source]

The design and manufacturing of connecting rods face several challenges, including the need for high strength-to-weight ratios and resistance to fatigue. Innovations in materials science and engineering have led to the development of lighter, stronger connecting rods that can withstand the increasing demands of modern engines. Additionally, the use of computer-aided design (CAD) and simulation has improved the precision and efficiency of connecting rod production.

Conclusion[edit | edit source]

The connecting rod is a vital component of the mechanical systems in internal combustion engines and compressors. Its design and material composition have evolved to meet the demands of modern machinery, making it a key factor in the performance and efficiency of these systems.

Search WikiMD

Ad.Tired of being Overweight? Try W8MD's physician weight loss program.

Semaglutide (Ozempic / Wegovy and Tirzepatide (Mounjaro / Zepbound) available.

Advertise on WikiMD

|

WikiMD's Wellness Encyclopedia |

| Let Food Be Thy Medicine Medicine Thy Food - Hippocrates |

Translate this page: - East Asian

中文,

日本,

한국어,

South Asian

हिन्दी,

தமிழ்,

తెలుగు,

Urdu,

ಕನ್ನಡ,

Southeast Asian

Indonesian,

Vietnamese,

Thai,

မြန်မာဘာသာ,

বাংলা

European

español,

Deutsch,

français,

Greek,

português do Brasil,

polski,

română,

русский,

Nederlands,

norsk,

svenska,

suomi,

Italian

Middle Eastern & African

عربى,

Turkish,

Persian,

Hebrew,

Afrikaans,

isiZulu,

Kiswahili,

Other

Bulgarian,

Hungarian,

Czech,

Swedish,

മലയാളം,

मराठी,

ਪੰਜਾਬੀ,

ગુજરાતી,

Portuguese,

Ukrainian

Medical Disclaimer: WikiMD is not a substitute for professional medical advice. The information on WikiMD is provided as an information resource only, may be incorrect, outdated or misleading, and is not to be used or relied on for any diagnostic or treatment purposes. Please consult your health care provider before making any healthcare decisions or for guidance about a specific medical condition. WikiMD expressly disclaims responsibility, and shall have no liability, for any damages, loss, injury, or liability whatsoever suffered as a result of your reliance on the information contained in this site. By visiting this site you agree to the foregoing terms and conditions, which may from time to time be changed or supplemented by WikiMD. If you do not agree to the foregoing terms and conditions, you should not enter or use this site. See full disclaimer.

Credits:Most images are courtesy of Wikimedia commons, and templates, categories Wikipedia, licensed under CC BY SA or similar.

Contributors: Prab R. Tumpati, MD