Mineral processing

Mineral processing is a branch of extractive metallurgy concerned with the physical and chemical transformation of ore into valuable minerals and metals. This field covers various processes aimed at extracting metals from their ores and involves a series of steps including ore dressing, crushing and grinding, screening, gravity separation, flotation, and dewatering. Mineral processing is a critical aspect of the mining industry, ensuring the economic viability of mining operations by increasing the grade of ore concentrates and reducing the amount of waste material.

Overview[edit | edit source]

Mineral processing begins with the extraction of ore from the earth, which is then subjected to various processes to increase the concentration of the desired mineral. The choice of specific techniques depends on the nature of the ore, the mineral composition, and the required purity of the final product. The process typically involves three major stages: comminution, beneficiation, and dewatering.

Comminution[edit | edit source]

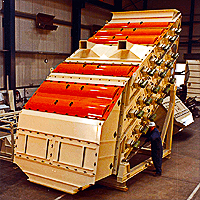

Comminution is the process of reducing the size of the ore to facilitate further processing. This is achieved through crushing and grinding operations. Crushing reduces large rocks to smaller pieces, and grinding further reduces those pieces to a powder or fine grains. This stage is crucial for increasing the surface area of the mineral particles, which enhances the effectiveness of subsequent beneficiation processes.

Beneficiation[edit | edit source]

Beneficiation involves separating valuable minerals from the waste rock (gangue). This can be achieved through various methods, including:

- Gravity separation: Utilizes the difference in density between valuable minerals and gangue.

- Magnetic separation: Employs magnetic properties of minerals to separate them from non-magnetic gangue.

- Flotation: A process where valuable minerals are separated from waste rock by inducing them to gather on the surface of a froth layer.

- Leaching: Involves dissolving valuable metals from the ore using a solvent.

Each of these methods has its specific applications and is chosen based on the physical and chemical properties of the ore.

Dewatering[edit | edit source]

The final step in mineral processing is dewatering, which removes water from the concentrate and tailings. This is typically achieved through thickening, filtration, or drying. Dewatering is essential for reducing transportation costs and preparing the concentrate for smelting or further processing.

Environmental Considerations[edit | edit source]

Mineral processing has significant environmental impacts, including water pollution, soil degradation, and the generation of waste material. Modern practices focus on minimizing these impacts through the recycling of water, the use of less toxic chemicals in processes like flotation, and the responsible disposal of waste.

Future Directions[edit | edit source]

Advancements in mineral processing technology continue to focus on improving efficiency, reducing environmental impact, and increasing the recovery rates of valuable minerals. Innovations such as machine learning and artificial intelligence are being explored for optimizing various processes within mineral processing.

Search WikiMD

Ad.Tired of being Overweight? Try W8MD's physician weight loss program.

Semaglutide (Ozempic / Wegovy and Tirzepatide (Mounjaro / Zepbound) available.

Advertise on WikiMD

|

WikiMD's Wellness Encyclopedia |

| Let Food Be Thy Medicine Medicine Thy Food - Hippocrates |

Translate this page: - East Asian

中文,

日本,

한국어,

South Asian

हिन्दी,

தமிழ்,

తెలుగు,

Urdu,

ಕನ್ನಡ,

Southeast Asian

Indonesian,

Vietnamese,

Thai,

မြန်မာဘာသာ,

বাংলা

European

español,

Deutsch,

français,

Greek,

português do Brasil,

polski,

română,

русский,

Nederlands,

norsk,

svenska,

suomi,

Italian

Middle Eastern & African

عربى,

Turkish,

Persian,

Hebrew,

Afrikaans,

isiZulu,

Kiswahili,

Other

Bulgarian,

Hungarian,

Czech,

Swedish,

മലയാളം,

मराठी,

ਪੰਜਾਬੀ,

ગુજરાતી,

Portuguese,

Ukrainian

Medical Disclaimer: WikiMD is not a substitute for professional medical advice. The information on WikiMD is provided as an information resource only, may be incorrect, outdated or misleading, and is not to be used or relied on for any diagnostic or treatment purposes. Please consult your health care provider before making any healthcare decisions or for guidance about a specific medical condition. WikiMD expressly disclaims responsibility, and shall have no liability, for any damages, loss, injury, or liability whatsoever suffered as a result of your reliance on the information contained in this site. By visiting this site you agree to the foregoing terms and conditions, which may from time to time be changed or supplemented by WikiMD. If you do not agree to the foregoing terms and conditions, you should not enter or use this site. See full disclaimer.

Credits:Most images are courtesy of Wikimedia commons, and templates, categories Wikipedia, licensed under CC BY SA or similar.

Contributors: Prab R. Tumpati, MD