Tempering (metallurgy)

Tempering is a heat treatment process used in metallurgy to increase the toughness of iron-based alloys, most notably steel. By carefully controlling the temperature and time to which the material is subjected, the physical properties such as ductility and toughness can be improved, making the material more workable and less prone to fracture. Tempering is often performed after quenching, which increases the hardness of the metal. The combination of quenching and tempering is essential in the production of strong, resilient steel components.

Process[edit | edit source]

The process of tempering involves heating the quenched steel to a temperature below its eutectoid temperature, which is approximately 727°C (1341°F) for most steels. This temperature is held constant for a period of time, then the steel is allowed to cool in still air. The specific temperature and time depend on the desired properties of the material and its composition. Lower tempering temperatures, typically between 150°C to 250°C (302°F to 482°F), will increase the hardness and strength of the steel, while higher temperatures, up to 650°C (1202°F), will enhance toughness at the expense of reducing hardness.

Purpose[edit | edit source]

The primary purpose of tempering is to achieve a balance between hardness and toughness. Without tempering, quenched steel is too brittle for most practical applications. Tempering reduces the brittleness while maintaining a significant portion of the hardness gained during quenching. This makes the steel more suitable for critical applications such as machine parts, cutting tools, and structural components.

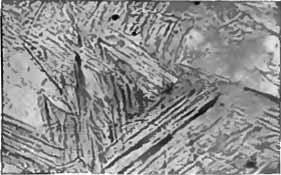

Microstructure Changes[edit | edit source]

During tempering, the microstructure of the steel changes. The extremely hard martensite formed during quenching is partially converted to bainite or ferrite and cementite, depending on the tempering temperature. These transformations redistribute and reduce the stresses and strains within the crystal structure of the steel, which are responsible for its brittleness after quenching.

Applications[edit | edit source]

Tempered steel is used in a variety of applications where durability and resistance to wear are essential. Common uses include:

- Automotive components such as gears, shafts, and axles

- Cutting tools like knives, saws, and drills

- Construction materials, including beams, bars, and rebars

- Firearms and military equipment

Advantages and Limitations[edit | edit source]

The main advantage of tempering is the ability to tailor the mechanical properties of steel to suit specific applications. However, the process requires precise control over temperature and time, making it somewhat complex. Additionally, there is always a trade-off between hardness and toughness; increasing one typically decreases the other.

See Also[edit | edit source]

| This article is a stub. You can help WikiMD by registering to expand it. |

Search WikiMD

Ad.Tired of being Overweight? Try W8MD's physician weight loss program.

Semaglutide (Ozempic / Wegovy and Tirzepatide (Mounjaro / Zepbound) available.

Advertise on WikiMD

|

WikiMD's Wellness Encyclopedia |

| Let Food Be Thy Medicine Medicine Thy Food - Hippocrates |

Translate this page: - East Asian

中文,

日本,

한국어,

South Asian

हिन्दी,

தமிழ்,

తెలుగు,

Urdu,

ಕನ್ನಡ,

Southeast Asian

Indonesian,

Vietnamese,

Thai,

မြန်မာဘာသာ,

বাংলা

European

español,

Deutsch,

français,

Greek,

português do Brasil,

polski,

română,

русский,

Nederlands,

norsk,

svenska,

suomi,

Italian

Middle Eastern & African

عربى,

Turkish,

Persian,

Hebrew,

Afrikaans,

isiZulu,

Kiswahili,

Other

Bulgarian,

Hungarian,

Czech,

Swedish,

മലയാളം,

मराठी,

ਪੰਜਾਬੀ,

ગુજરાતી,

Portuguese,

Ukrainian

Medical Disclaimer: WikiMD is not a substitute for professional medical advice. The information on WikiMD is provided as an information resource only, may be incorrect, outdated or misleading, and is not to be used or relied on for any diagnostic or treatment purposes. Please consult your health care provider before making any healthcare decisions or for guidance about a specific medical condition. WikiMD expressly disclaims responsibility, and shall have no liability, for any damages, loss, injury, or liability whatsoever suffered as a result of your reliance on the information contained in this site. By visiting this site you agree to the foregoing terms and conditions, which may from time to time be changed or supplemented by WikiMD. If you do not agree to the foregoing terms and conditions, you should not enter or use this site. See full disclaimer.

Credits:Most images are courtesy of Wikimedia commons, and templates, categories Wikipedia, licensed under CC BY SA or similar.

Contributors: Prab R. Tumpati, MD