Relief valve

Relief Valve

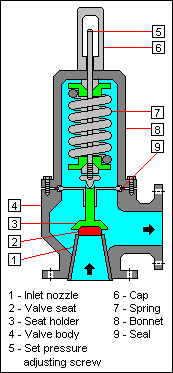

A relief valve is a type of safety valve used to control or limit the pressure in a system; pressure might otherwise build up and create a process upset, instrument or equipment failure, or fire. The relief valve is designed to open at a predetermined set pressure to protect pressure vessels and other equipment from being subjected to pressures that exceed their design limits. When the set pressure is exceeded, the relief valve becomes the path of least resistance as the valve is forced open and a portion of the fluid is diverted through the auxiliary route. The diverted fluid (gas, liquid, or sometimes both) is usually routed through a piping system known as a flare or relief header to a central, controlled location where it can be processed or safely released into the atmosphere.

Operation[edit | edit source]

Relief valves operate by opening at a preset pressure level and discharging fluid until the pressure within the system drops to a safe level. The valve then closes, preventing any further flow of fluid. Relief valves are an essential component of any system that generates pressure, providing a simple, automatic means of preventing the pressure from exceeding a predetermined limit. They are commonly used in gas storage tanks, pressure vessels, and piping systems.

Types of Relief Valves[edit | edit source]

There are several types of relief valves, each designed for specific applications and operating conditions:

- Safety Valve: Specifically designed for steam and air services, it opens rapidly and fully when the set pressure is reached.

- Pressure Relief Valve: Opens proportionally as the pressure exceeds the set limit. Used for liquid services.

- Vacuum Relief Valve: Designed to admit pressure into a system when the internal pressure drops below the set level.

- Pilot-operated Relief Valve: Uses system pressure to seal the valve and a pilot mechanism to relieve pressure once the set point is reached.

Applications[edit | edit source]

Relief valves are critical for the safety of the chemical, oil and gas, and power generation industries, among others. They protect equipment from damage caused by excessive pressure and prevent potential accidents associated with overpressure conditions.

Installation and Maintenance[edit | edit source]

Proper installation and maintenance of relief valves are crucial for their effective operation. They must be installed in a manner that allows them to respond to pressure changes swiftly. Regular maintenance checks are necessary to ensure that they are free from defects and operational at all times.

Regulations and Standards[edit | edit source]

The design and operation of relief valves are governed by industry standards and regulations to ensure safety and reliability. Notable standards include those from the American Society of Mechanical Engineers (ASME), which provides guidelines for the design and manufacture of relief valves.

Transform your life with W8MD's budget GLP1 injections from $125 and up biweekly

W8MD offers a medical weight loss program NYC and a clinic to lose weight in Philadelphia. Our W8MD's physician supervised medical weight loss centers in NYC provides expert medical guidance, and offers telemedicine options for convenience.

Why choose W8MD?

- Comprehensive care with FDA-approved weight loss medications including:

- loss injections in NYC both generic and brand names:

- weight loss medications including Phentermine, Qsymia, Contrave, Diethylpropion etc.

- Accept most insurances for visits or discounted self pay cost.

- Generic weight loss injections starting from just $125.00 for the starting dose

- In person weight loss NYC and telemedicine medical weight loss options in New York city available

Book Your Appointment

Start your NYC weight loss journey today at our NYC medical weight loss, and Philadelphia and visit Philadelphia medical weight loss Call (718)946-5500 for NY and 215 676 2334 for PA

Search WikiMD

Ad.Tired of being Overweight? Try W8MD's NYC physician weight loss.

Semaglutide (Ozempic / Wegovy and Tirzepatide (Mounjaro / Zepbound) available. Call 718 946 5500.

Advertise on WikiMD

|

WikiMD's Wellness Encyclopedia |

| Let Food Be Thy Medicine Medicine Thy Food - Hippocrates |

Translate this page: - East Asian

中文,

日本,

한국어,

South Asian

हिन्दी,

தமிழ்,

తెలుగు,

Urdu,

ಕನ್ನಡ,

Southeast Asian

Indonesian,

Vietnamese,

Thai,

မြန်မာဘာသာ,

বাংলা

European

español,

Deutsch,

français,

Greek,

português do Brasil,

polski,

română,

русский,

Nederlands,

norsk,

svenska,

suomi,

Italian

Middle Eastern & African

عربى,

Turkish,

Persian,

Hebrew,

Afrikaans,

isiZulu,

Kiswahili,

Other

Bulgarian,

Hungarian,

Czech,

Swedish,

മലയാളം,

मराठी,

ਪੰਜਾਬੀ,

ગુજરાતી,

Portuguese,

Ukrainian

Medical Disclaimer: WikiMD is not a substitute for professional medical advice. The information on WikiMD is provided as an information resource only, may be incorrect, outdated or misleading, and is not to be used or relied on for any diagnostic or treatment purposes. Please consult your health care provider before making any healthcare decisions or for guidance about a specific medical condition. WikiMD expressly disclaims responsibility, and shall have no liability, for any damages, loss, injury, or liability whatsoever suffered as a result of your reliance on the information contained in this site. By visiting this site you agree to the foregoing terms and conditions, which may from time to time be changed or supplemented by WikiMD. If you do not agree to the foregoing terms and conditions, you should not enter or use this site. See full disclaimer.

Credits:Most images are courtesy of Wikimedia commons, and templates, categories Wikipedia, licensed under CC BY SA or similar.

Contributors: Prab R. Tumpati, MD